In the food industry, control of the chemical and physical properties of ingredient is of paramount importance, both to ensure the quality, taste and nutritional characteristics of the finished product and to control the characteristics of the production process.

An important aspect in the characterization of powder food products is the determination of particle size. Particle size influences properties, taste and process behaviour; therefore, understanding the effect of different particle sizes on the properties of the ingredient and finished product is essential to a complete control of the production process.

To this end, it is critical to ensure a reliable milling process, and the only way to do this is to control particle size. The fastest and most accurate technique for determining particle size is undoubtedly laser diffraction: analysis of a dry sample in 5 seconds!

At Alfatestlab, we analyzed 6 powder ingredients for the QC department of one of our customers from food industry:

- Flour

- Coffee

- Brown sugar

- Cocoa

- Rice starch

- Sugar

The particle size of these ingredients influences the preparation of baked goods and can be critical in applications such as creams, icings, syrups, etc. where the presence of water induces swelling from particle hydration, which can alter palatability and more globally rheological properties.

Results

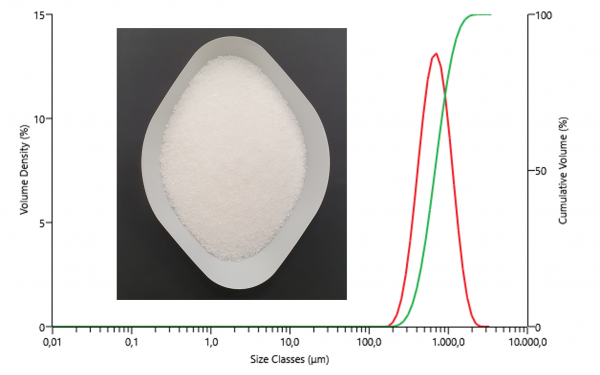

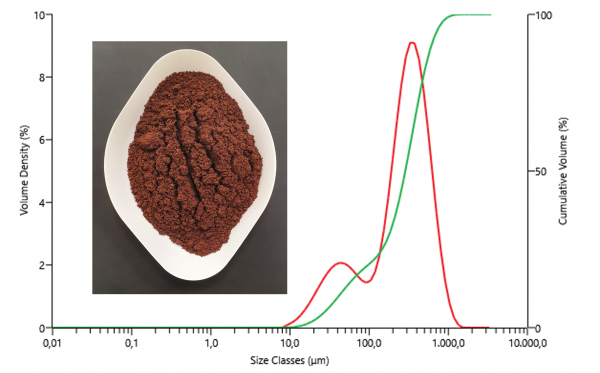

Below are the particle size distributions and numerical results obtained from the particle size analysis with dry dispersion of the 6 ingredients.

The results were in within the acceptable range stated by our customer and last but not least… were optimal for our recipe!!!

Flour

Coffee

Brown sugar

Cocoa

Rice starch

Sugar